WE ARE MADE IN THE USA | Always here, Always available

+1 410-604-2900

Knowledge Center

The latest from

Miltec.

-

Guide to Peak Performance

Is your UV curing system performing as it should? Are you constantly replacing overheated lamps? Maintaining a UV curing system is crucial to obtaining successful results in curing and saving money by reducing unexpected downtime caused by poorly maintained UV equipment. In this guide, you will learn: Download the Guide

-

Magnetrons

A magnetron is a high-vacuum tube that converts electrical energy into microwaves (a form of electromagnetic radiation with wavelengths shorter than other radio waves but longer than infrared waves) through the interaction of electrons and a magnetic field. Used primarily in microwave ovens and radar systems but also in UV Systems, magnetrons work as a pair and must be replaced as a pair. Magnetrons

-

UV Curing System

A UV curing system emits UV light to activate photoinitiators in the coating or ink. These photoinitiators generate free radicals that start a chain reaction, causing the material to cure or harden. Advantages of a UV Curing System The primary advantages of curing with UV light are significantly faster cure speeds compared to other comparable

-

Infrared Round Tube Emitters

Round tube IR emitters are a highly efficient and versatile solution for infrared heating technology. These emitters are designed to deliver exceptional performance across various industrial and commercial applications. This page explores the features, benefits, and applications of Round Tube IR Emitters, demonstrating why they are an optimal choice for anyone seeking effective infrared heating

-

UV Curing: The Basics

UV curing is the process by which UV light initiates a photochemical reaction of a UV-curable solution, causing the solution to polymerize.

-

Microwave UV System

What is a Microwave UV System? The microwave-powered electrodeless UV lamp is constructed from a quartz tube containing mercury and a noble gas. It is powered by applying microwave energy to the UV bulb, which excites the mercury into a plasma to produce UV light. What is UV Curing? UV curing is the process by

-

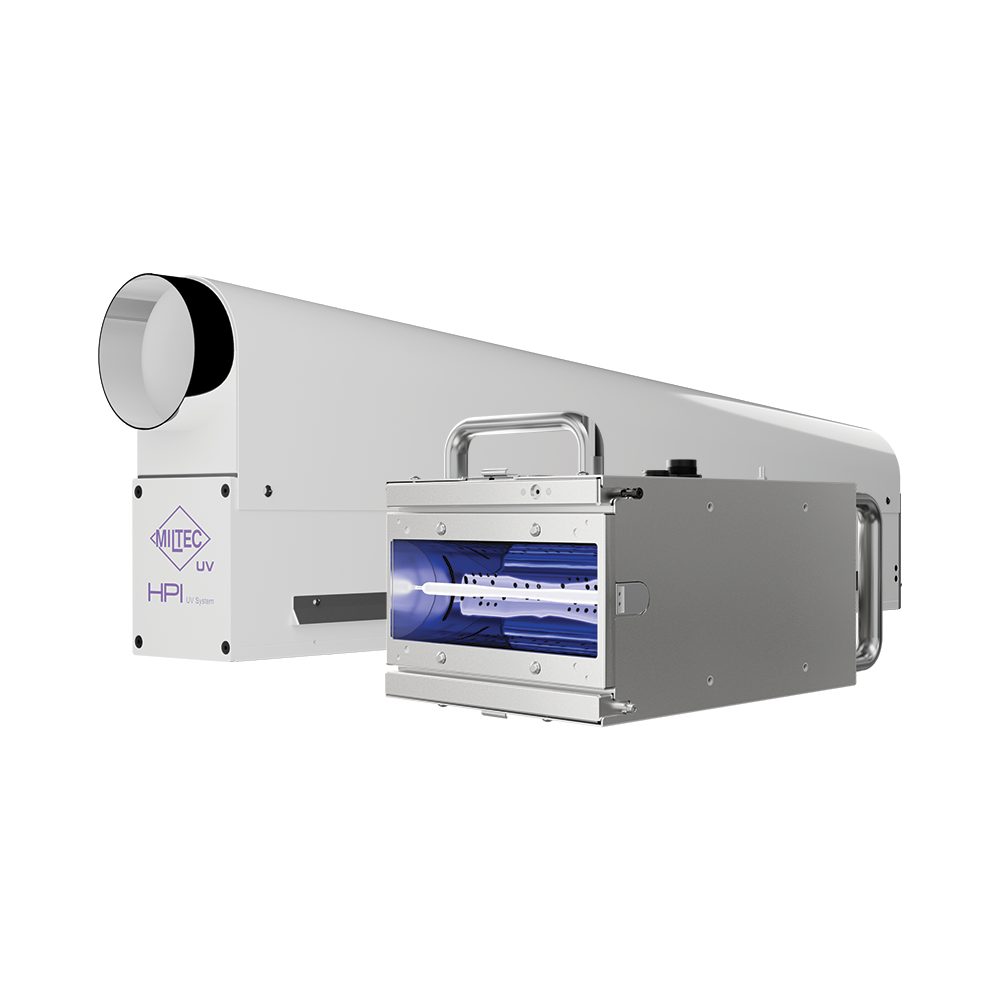

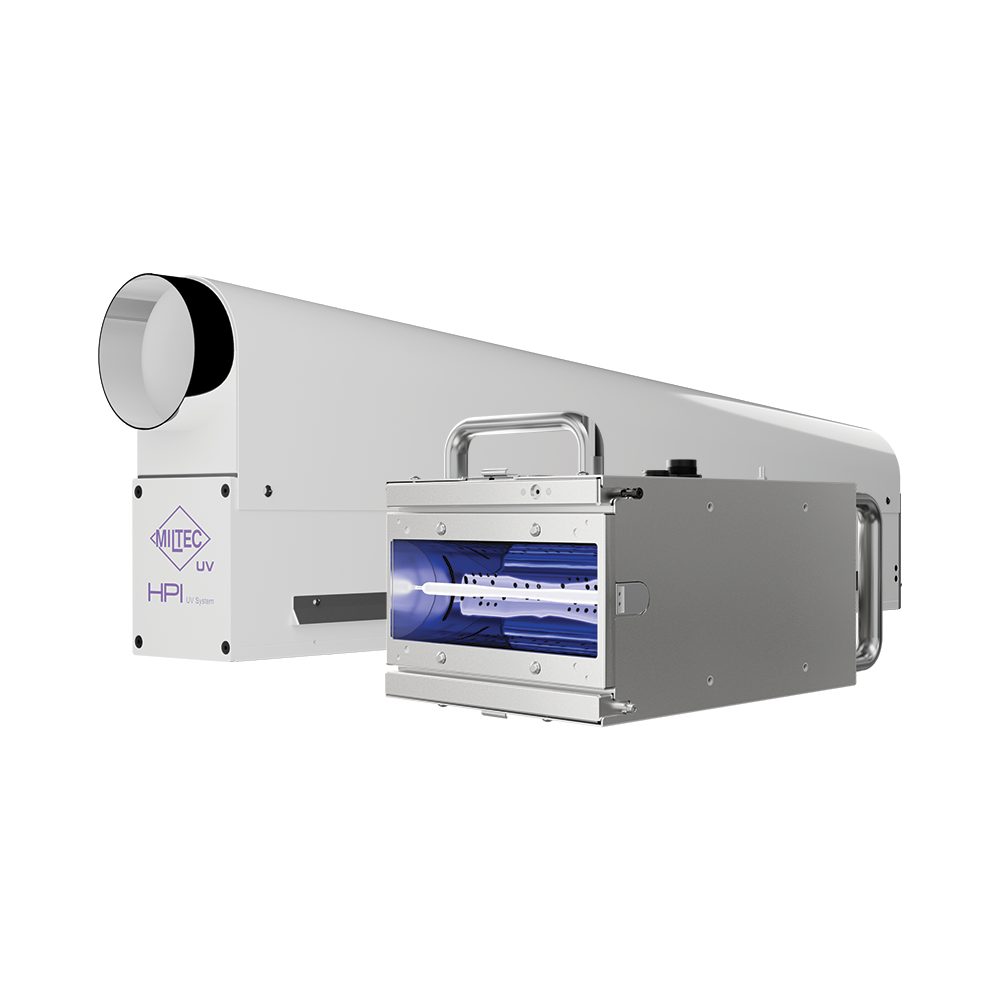

ARC UV System

What is an ARC UV System? An arc UV system comprises electrodes at each end of a tubular-shaped quartz lamp, commonly filled with a blend of mercury and noble gas. By applying electrical discharge from these electrodes within the tubular lamp, the mercury is stimulated into a plasma state, emitting light across the entire UV

-

Maintain your UV Reflector

The reflector, a crucial component of UV systems, is responsible for 65%-70% of the total UV energy output. However, its coatings may deteriorate over time, resulting in a noticeable decrease in energy output. We often receive questions about when to replace the reflector. To assist you, we’ve outlined two inspections to evaluate the condition of

-

Is Your UV Curing System Ready for Summer?

With summer fast approaching, it’s time to give your UV curing system a spring cleaning to help reduce pesky heat issues before they arise. Just like you might do a spring cleaning at home to prepare for the warmer weather, it’s a good idea to give your UV curing system a similar tune-up. Here are

Our Team

Our people set us apart.

Our friendly team of experts is always here to help.

Count on them for solutions, ideas, support, and guidance.

Headquarters

146 Log Canoe Circle

Stevensville, Maryland 21666 USA

Support

Phone: +1 410-604-2900

Email: service@miltec.com

After Hours Technical Support

(5 pm – 8 am EST) (GMT -5):

+1 410-604-2900

Sales

Phone: +1 410-604-2900

Fax: (+1) 410-604-2906

Email: sales@miltec.com

Photography by David Bohrer, National Assoc. of Manufacturers and Gary Landsman, Gary Landsman Photography

©2025 Miltec UV. All Rights Reserved. Privacy Policy / Terms and Conditions