UV curing optical fiber is an efficient system, that enables fast line speeds while producing a high quality product. Microwave powered UV lamp systems utilizing electrodeless UV bulbs offer the perfect solution for curing coatings or inks applied to optical fiber on high speed draw towers or coloring machines, as well as specialty fiber applications.

The process for optical fiber is: Glass is melted into skinny strands and cooled. Then, the fiber goes through a laser diameter gauge to measure and monitor its diameter. A coating is applied to the fiber, which is then cured 360 degrees around the outside of the optical fiber using high peak irradiance UV light. Typically, two coatings are applied to create a soft and hard outer layer. Finally, the fiber is spooled onto take-up reels.

Why is Optical Fiber UV Cured?

The coating applied to the optical fiber serves as a barrier between the fiber and the external environment, providing mechanical strength, protection against moisture, and resistance to abrasion. The coating material is typically a polymer applied in a very thin layer around the outside of the fiber and cured using UV light. UV curing makes this process quick and efficient due to the high peak irradiance UV light, which allows for maximum fiber production speeds.

The UV coating also protects against decay from cable gels. Cable gels prevent breaking from bending and water from getting to the fiber, but they also degrade the cable over time. The UV-cured coating helps prevent this decay.

Applications of UV Curing for Optical Fiber

- UV coatings applied to the fiber on optical fiber draw towers or specialty fiber machines

- UV inks applied on optical fiber for color coding the fiber

- UV inks applied to optical fiber ribbon cable

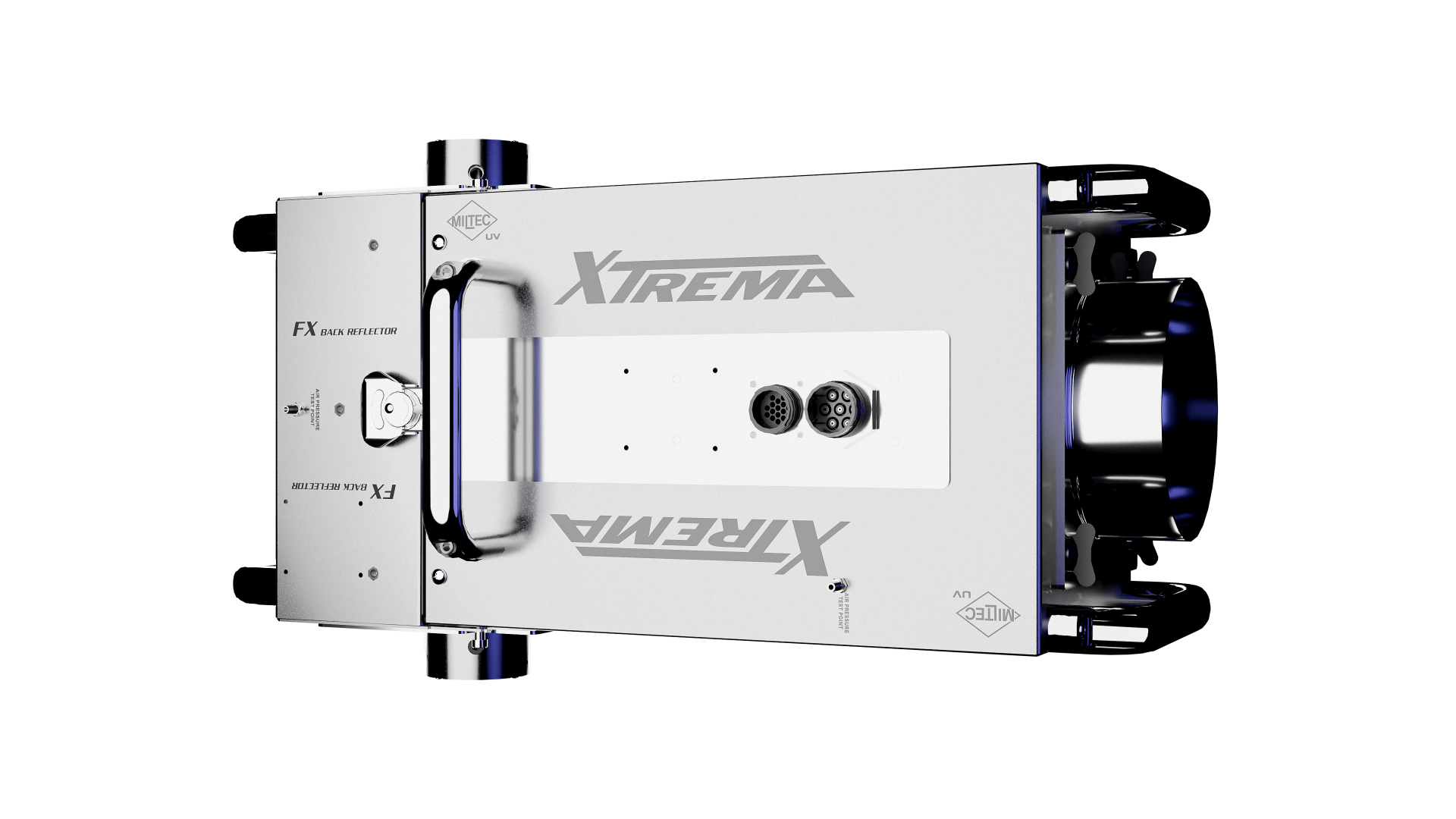

Xtrema ECO‘s Advantages for UV Curing Optical Fiber

Our advanced optics concentrate more UV output at the fiber, resulting in faster line speeds. We provide significant energy and operating savings through efficient design and easy maintenance features. Miltec’s Xtrema ECO UV systems offer many significant benefits to the optical fiber manufacturer.

Benefits

- Up to 35% higher UV intensity at the fiber leads to faster line speeds

- 33% or greater energy savings

- Easy on site repair and maintenance of power supplies and lamps

- Lower heat emissions resulting in cooler fiber surface temperatures

- Optimized cooling designed to maximize the life of all lamp parts

- Easy to retrofit (or upgrade) legacy microwave powered UV equipment

- Reduce downtime with easy bulb and reflector changeouts using our innovative “Quick Release” RF screen

- Long bulb life

- Stable UV spectral output

- Additive bulbs available for unique applications

- Robust and proven design

Learn more about Miltec UV’s curing systems for optical fiber when you read From Parts to Peak Irradiance: Innovation Drives Miltec UV on Wire & Cable magazine’s website.

APPLICATIONS DEVELOPMENT & TESTING LAB

Explore the possibilities. We’ll help.

Work alongside our Ph.D. chemists, engineers, and UV experts in our fully equipped UV Curing Applications Laboratory to develop new processes, achieve cost reduction, and improve production workflows for your application.