Always here, Always available

+1 410-604-2900

Knowledge Center

The latest from

Miltec.

-

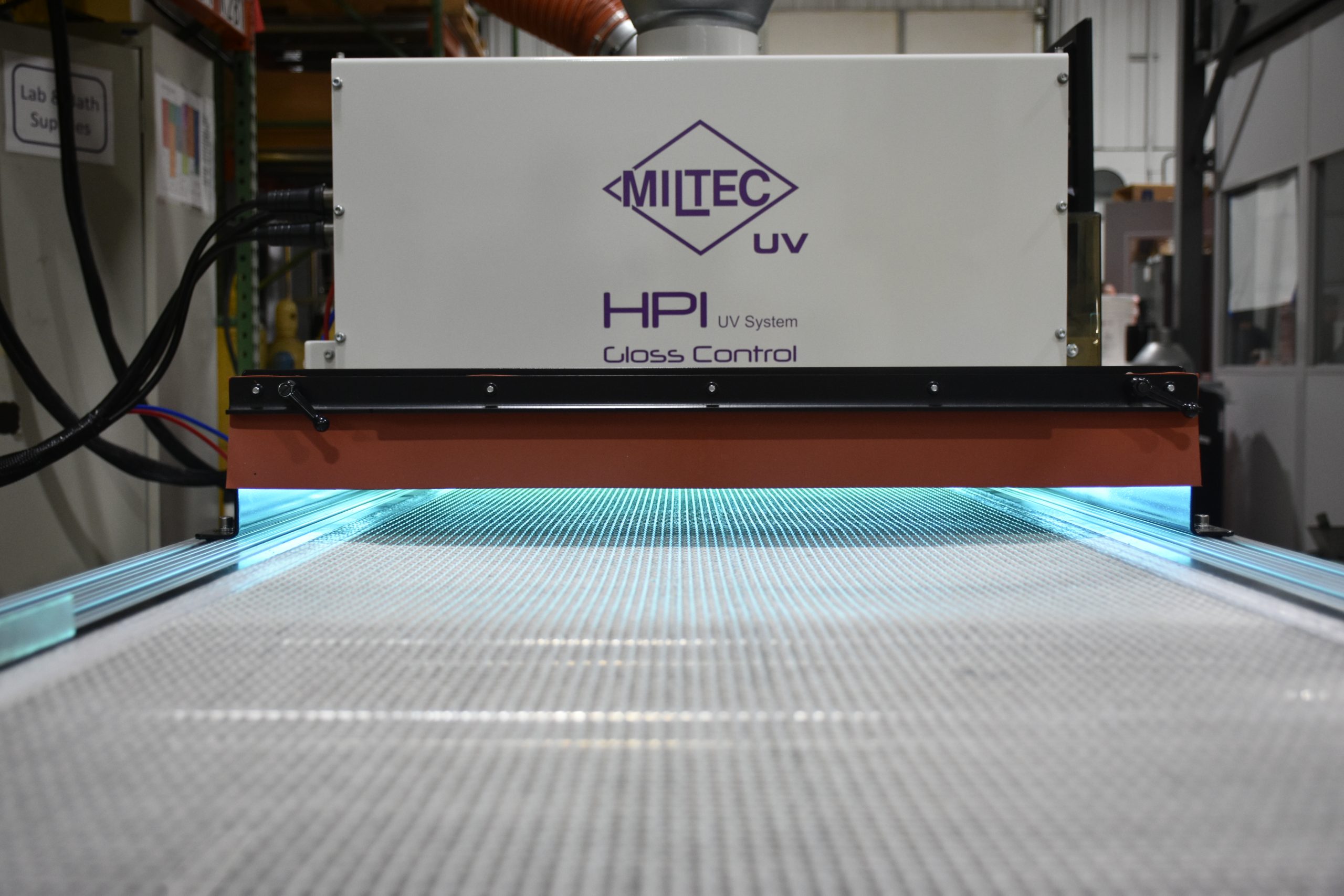

UV Chemistry: Your Formula for a Successful Cure

Miltec’s reputation for creating quality UV curing systems, parts, and components is a direct reflection of the innovations that come from our on-site Applications Testing Laboratory.

-

Understanding Ultraviolet Light

Ultraviolet light (UV) is a type of radiant energy that appears on the electromagnetic (EM) spectrum between visible light and x-rays. It has a shorter wavelength than visible light but higher energy (or frequency). The EM spectrum has seven regions based on wavelength and frequency/energy. UV Light from the Sun vs Man-made Sunlight contains only…

-

Cybersecurity in the Manufacturing Workplace

As a 2022 National Cybersecurity Alliance Champion, we take the security of our business seriously. And since it’s Cybersecurity Awareness Month we’re happy to share a few tips that manufacturers of all sizes can take to better protect themselves against cyberattacks. Identify “Crown Jewels” of Your Business Understanding what information cybercriminals are after most is…

-

How does UV curing work?

Answering your UV curing questions UV curing is a technology that has revolutionized the way we think about adhesive and coating applications. It is a process that involves using ultraviolet (UV) light to initiate a chemical reaction, which causes a liquid or semi-solid material to transform into a solid state. This process is widely used…

-

UV Curing – Is It Right For You?

UV light curing works by activating the photopolymerization to harden dyes, inks, and adhesives onto a surface with a specific wavelength of UV light. With UV light curing systems, you must use an appropriate light source and ink or adhesive to get the best results. Let’s take a look at the history, technology, and the…

-

5 Ways to Reduce Manufacturing Downtime

Downtime in the manufacturing process is one of the biggest causes of lost productivity. It delays the production process and ripples throughout the supply chain, ultimately affecting your ROI. Here are five ways to minimize manufacturing downtime, eliminate delays, and keep your business running smoothly. Cross-train employees. One of the most important aspects of running…

-

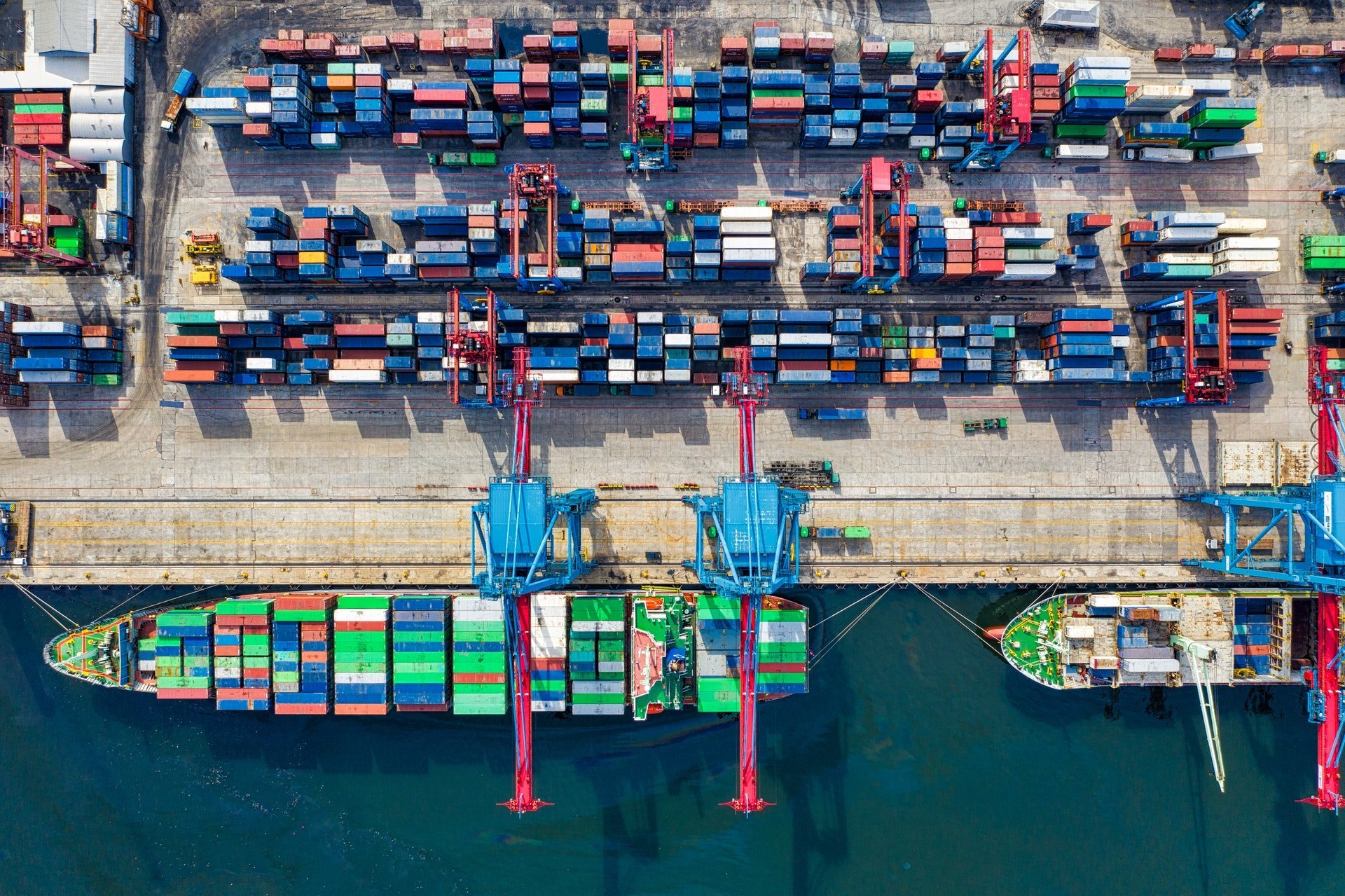

Made in America is Good for America

The pandemic, tensions overseas, supply chain issues…if those haven’t given you a reason to consider sourcing your products from companies right here in the United States, here are a few more.

-

The Future of Li-ion Battery Production is NMP-Free

N-Methylpyrrolidone, also known as N-Methyl-2-Pyrrolidone or NMP, is a colorless chemical solvent having a high boiling point, a high flash point, and a low vapor pressure. In many production processes, these characteristics are highly desired and made NMP a widely used solvent in the petrochemical and plastics industries, as well as in manufacturing. NMP is…

-

Supplier Selection, New Vendor Consideration

Just like when you buy a car, choosing a vendor takes time and should require an analysis of critical performance criteria, driven by quality and reliability standards, as well as an understanding of material cost and availability.

Our Team

Our people set us apart.

Our friendly team of experts is always here to help.

Count on them for solutions, ideas, support, and guidance.

Headquarters

146 Log Canoe Circle

Stevensville, Maryland 21666 USA

Support

Phone: +1 410-604-2900

Email: service@miltec.com

After Hours Technical Support

(5 pm – 8 am EST) (GMT -5):

+1 410-604-2900

Sales

Phone: +1 410-604-2900

Fax: (+1) 410-604-2906

Email: sales@miltec.com

Photography by David Bohrer, National Assoc. of Manufacturers and Gary Landsman, Gary Landsman Photography

©2025 Miltec UV. All Rights Reserved. Privacy Policy / Terms and Conditions

简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย