WE ARE MADE IN THE USA | Always here, Always available

+1 410-604-2900

Knowledge Center

The latest from

Miltec.

-

UV Power Supply Test Points Save Time & Money

Test points for microwave UV power supplies allow maintenance teams to quickly and easily troubleshoot the system’s three basic circuits: the photocell, filament, and magnetron current. Located on the front or back of the power supply, some units may have three sets and others only two but all the systems that utilize these tools have

-

Top 4 Benefits of Single, Reliable Vendor

In today’s fast-paced and competitive world, it is essential for manufacturers to operate with maximum efficiency and cost-effectiveness. One way to achieve this is by sourcing as many supplies as possible from one reliable, source rather than relying on multiple vendors. There are many benefits to consolidating your supply chain, and in this blog, we’ll

-

10 Ways Manufacturers Can Reduce Their Carbon Footprint

A guide to carbon-neutral practices and technologies As the world continues to grapple with the effects of climate change, businesses are increasingly being called upon to do their part in reducing their carbon footprint and promoting sustainability. By adopting environmentally-friendly practices and technologies, companies can not only help mitigate the negative impacts of climate change,

-

Thermal Drying or UV Curing?

The differences between light and heat for manufacturing processes When it comes to drying/curing methods in industrial processes, two popular methods are thermal drying and UV curing. Both methods are used to transform liquid or semi-liquid materials into solid forms by applying heat or UV radiation. In this blog post, we will discuss the difference

-

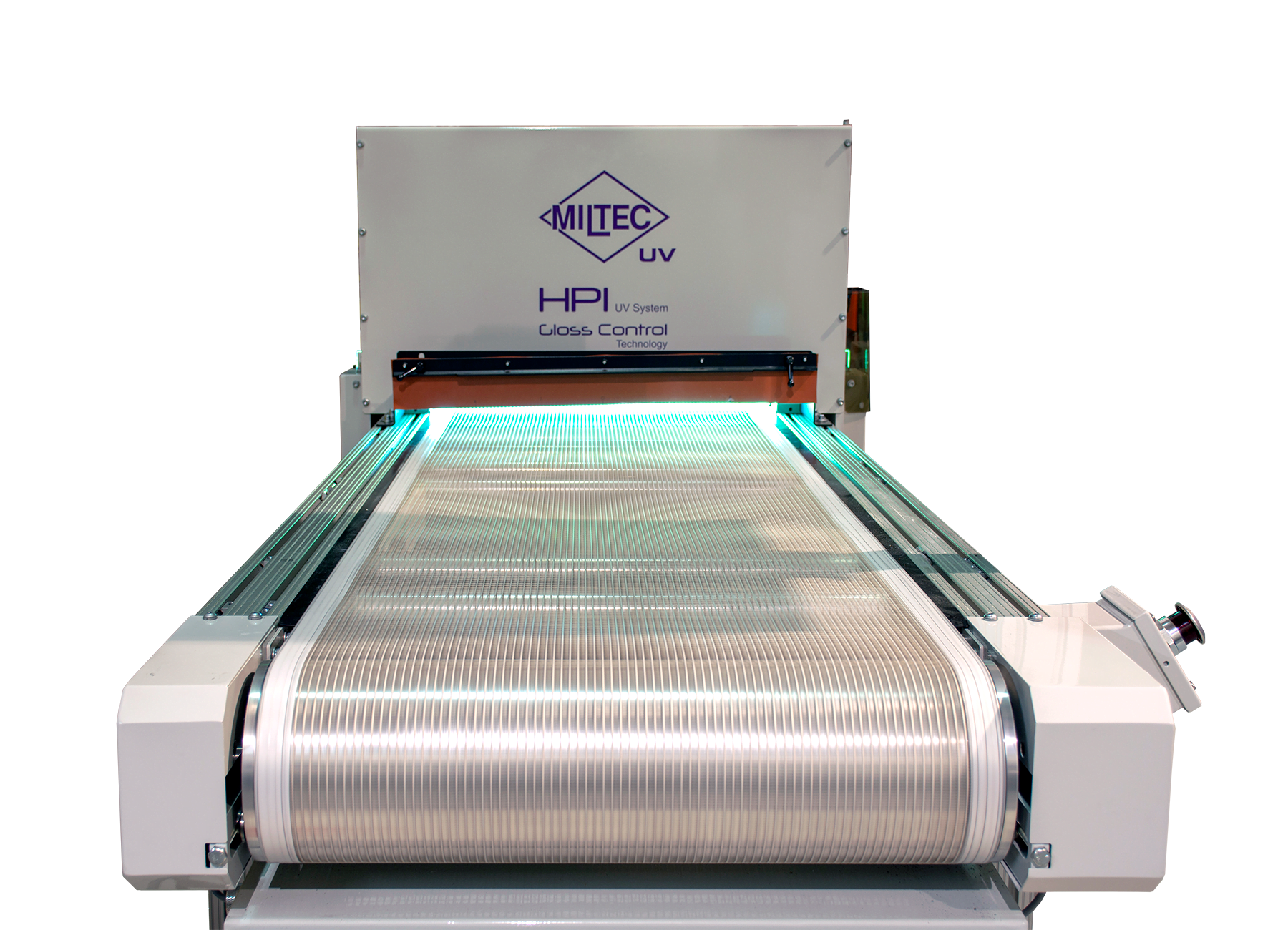

The Ultimate Guide to UV Curing Conveyors

For many, industrial UV conveyor systems are an essential part of the UV curing process. From the size and type of the material to the speed, understanding the different types, features, and issues of UV curing conveyors help you make an informed decision for your production needs. Types of UV Curing Conveyor Belts Open Mesh

-

UV System Cooling and Air Flow

Part 1 in Miltec UV’s Maintaining UV System Performance Blog Series Is your UV curing system performing as it should? Are you constantly replacing overheated lamps? Maintaining a UV curing system is crucial to obtaining successful results in curing and saving money by reducing unexpected downtime caused by poorly maintained UV equipment. In this blog

-

The Importance of Light Shielding in UV Curing

Part 2 in Miltec UV’s Maintaining UV System Performance Blog Series The primary purpose of light shielding in UV curing is to ensure operator safety from any direct UV stray light exposure. Good light shielding materials in and around the UV lamp housing will protect the lamp module components and the production machine it mounts.

-

UV Reflector Performance

Part 3 in Miltec UV’s Maintaining UV System Performance Blog Series UV curing reflectors typically have a semi-elliptical or parabolic geometry that wraps around the upper half and runs the entire length of the UV bulb. These lamp reflectors are an essential part of the UV system because they are responsible for reflecting about 65%

-

UV Ballast & Bulb Maintenance

Part 4 in Miltec UV’s Maintaining UV System Performance Blog Series Routine lamp maintenance is important to maintaining a healthy UV curing system. It is important to try to keep lamps as clean as possible to ensure consistent UV output and prolong their useful life. Most UV lamps operate in industrial environments that are typically

Our Team

Our people set us apart.

Our friendly team of experts is always here to help.

Count on them for solutions, ideas, support, and guidance.

Headquarters

146 Log Canoe Circle

Stevensville, Maryland 21666 USA

Support

Phone: +1 410-604-2900

Email: service@miltec.com

After Hours Technical Support

(5 pm – 8 am EST) (GMT -5):

+1 410-604-2900

Sales

Phone: +1 410-604-2900

Fax: (+1) 410-604-2906

Email: sales@miltec.com

Photography by David Bohrer, National Assoc. of Manufacturers and Gary Landsman, Gary Landsman Photography

©2025 Miltec UV. All Rights Reserved. Privacy Policy / Terms and Conditions