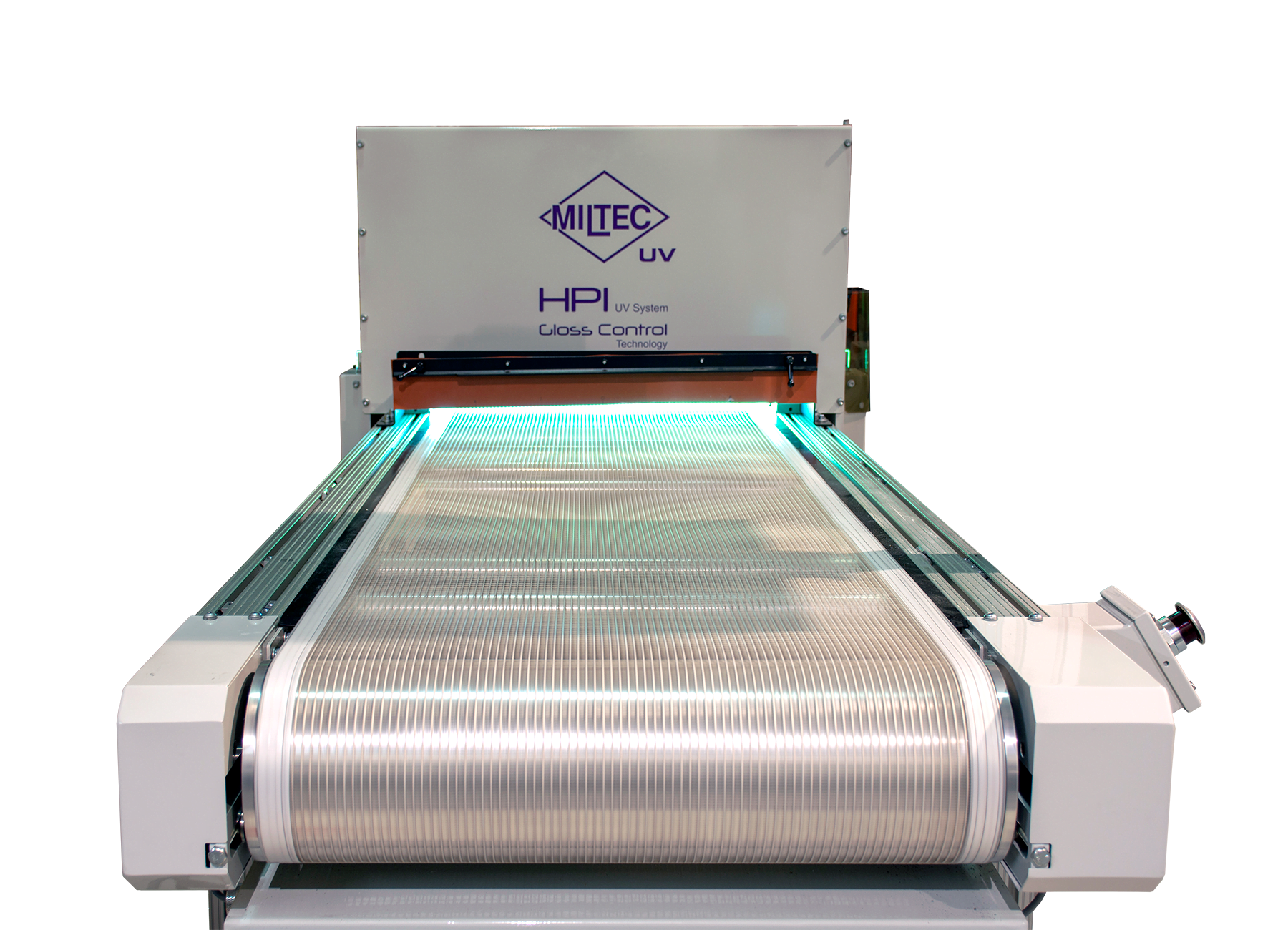

For many, industrial UV conveyor systems are an essential part of the UV curing process. From the size and type of the material to the speed, understanding the different types, features, and issues of UV curing conveyors help you make an informed decision for your production needs.

Types of UV Curing Conveyor Belts

Open Mesh Conveyor Belts that are woven but are not made to stretch: These types of belts are made with UV resistant materials that can withstand high temperatures. These conveyor belts require special consideration and design to ensure reliable conveyor belt tracking and long life. This conveyor belt type is not recommended for conveying products on an incline because they tend to have a “slippery” surface and can cause parts to slide. Open mesh conveyor belts are not recommended for abrasive or heavy load applications like stone or metal objects as they can be damaged.

Rubber-coated drive rollers will effectively grip open mesh UV curing conveyor belts and prevent slippage between the drive roller and conveyor belt. About 2.5 to 1 conveyor length-to-width ratio is required to ensure tracking of open mesh conveyor belts. Belts wider than 36 inches should have an external mechanical tracking mechanism to ensure the conveyor belt does not track off the end of the roller.

Special attention needs to be taken for proper tracking. Take-up roller adjustments are not a reliable way to track open mesh belts. For narrow belts, a tracking bead can be stitched to the bottom of the belt (typically on one edge) which will ride in a mating groove in the conveyor rollers to keep the conveyor belt on track.

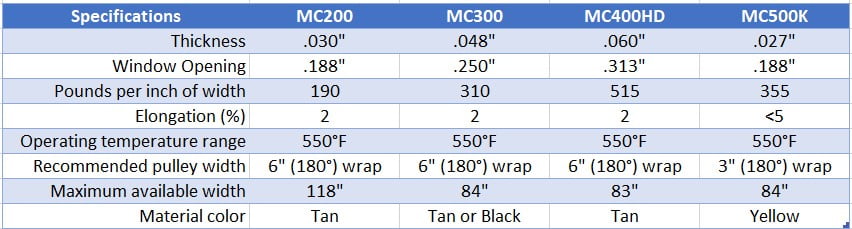

Open Mesh Conveyor Belts that are made to allow a small amount of stretching: These types of open mesh conveyor belts have a higher tensile strength than previously discuss open mesh conveyor belt and can withstand temperatures up to 550° F because of the material used in this woven pattern. It can be used for roller diameters as small as 3 inches and used to convey heavy loads and parts with sharp edges.

With 2.5 to 1 conveyor length-to-width ratio to ensure good tracking, the this type of open mesh conveyor belt can be easier to track than the previously discussed open mesh conveyor belt and can be used with a crowned roller for tracking purposes because it has higher stretch properties.

What the open mesh belt with the higher stretch property doesn’t do well is hold up to high intense UV exposure and therefore, it is not typically recommended for UV applications.

Solid, Rubber Belts: Made of a special material that is UV resistant and can withstand high temperatures, solid rubber belts offer excellent stretch properties. The rubber conveyor belt is more robust and durable than open mesh belts and can convey heavy objects with good wear and tear quality. True to its name, the rubber belt has good stretch characteristics and is easy to track with tracking bead or crowned roller.

With no bottom shielding required, the rubber belt’s high friction grips parts of all sizes with a temperature resistance up to 325°F. Trapezoidal crowned rollers can be used on all solid rubber belting that will stretch and conform to the taper on the roller, which will serve as the tracking mechanism for the conveyor belt.

UV Curing Conveyor Belt Seam Styles

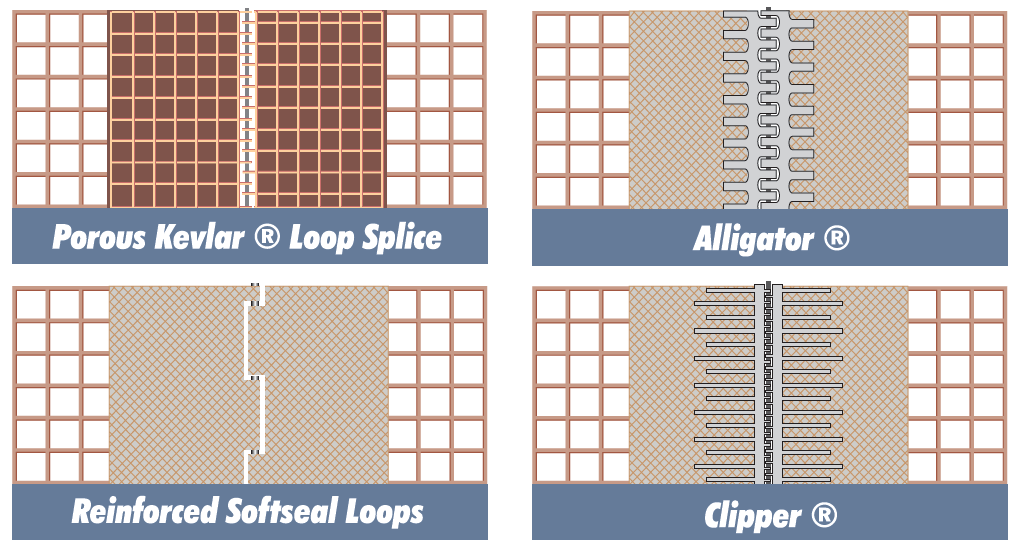

Alligator and Clipper Seams: Alligator and clipper splices are strong metal (or stainless steel if needed) lacings for pulleys. The alligator seams is for use with 127mm diameter or larger pulleys, while the clipper, with its additional flexibility, conforms well to smaller diameter pulleys. Both can be made of stainless steel if necessary, and an optional flap can be added to the top or bottom, so the seam does not come into contact with the substrate.

Reinforced Softseal Loops: A non-metallic seam constructed with a special coated UV resistant fabric, softseal loops are used in food service and are suitable for microwave ovens when used in conjunction with a non-metal pin. A flap is typically not required for this seam and it is relatively easy to thread the pin through this seam.

Porous Loop Splice: Only available with open mesh belts with stretchable woven material, air will flow through this type of seam making it suitable for vacuum hold-down conveyors. This seam is recommended for belt widths of 24 inches or less. A flap is typically not required for this seam. The only drawback is that it’s difficult to thread the pin through the seam.

Staying on Track

The tracking of a conveyor belt is always a challenge and must be carefully considered when designing and specifying a new or existing UV curing conveyor system. If the proper tracking method and conveyor belt is not used, the result will be a conveyor belt that tracks off the edge of the conveyor rollers, which will quickly destroy the conveyor belt. There are several methods used for conveyor belt tracking including automatic belt trackers, crowned roller method, and utilizing belt tracking beads into mating grooves.

Solid or open mesh belts less than 36” in width can typically be tracked using a tracking bead on the bottom of the belt guided by a groove in the conveyor rollers. Miltec recommends an automatic tracker on all solid fabric or woven open mesh belting over 36-inches wide and 30-foot long. Only straight rollers machined to a constant outside diameter should be used on solid or open mesh belting. Never use crowned pulleys (or tapered with varying diameter along the roller length) on solid or open mesh belts that are not made to stretch. If a crowned roller/pulley is used on these “non-elastic” belts, this material will not stretch and will develop a center crease down the entire length of the belt. Trying to track a solid or open mesh belt is like trying to track a pane of glass, it doesn’t want to distort and will break!

Driving Open Mesh UV Resistant Conveyor Belts: A word about driving these types of open mesh conveyor belts. A belt should be pulled through the oven or conveyor, never pushed. A smooth metal pulley and a slippery open mesh conveyor belt is a bad combination. The more tension you apply to the open mesh conveyor belt to get it to drive, the more slippery the conveyor belt’s surface becomes. To overcome this, the drive pulley must be lagged or covered with an EPDM or similar rubber that will help grip the slippery surface of the open mesh conveyor belt. In higher temperature applications where the belt doesn’t have enough time to cool down before it contacts the roller, a silicone rubber lagging on the roller in the range of 30-50 is necessary.

A open mesh UV curing conveyor belt should have as little tension applied to it as possible, but enough tension to grip well with the drive roller. How little? Only enough to carry the product along the conveyor or through the oven. Over-tensioning the belt will diminish its useful life.

Roller diameters open mesh belts should be as large as possible. The bigger the diameter, the easier it will be to drive and track the belt. Our recommendation for minimum roller diameters are shown in the table on this page.

Preparing for Purchase

In order to get a fast quote for your new or replacement conveyor belt, you’ll need to do a little homework. Typically, your supplier will need the following:

- Length and width of the belt (in inches)?

- Diameter of the pulley?

- Material type?

- Splice type? (Alligator, Loop, Clipper or Softseal Loop)

- Is there a flap over the splice?

- How your current belt is tracked?

Miltec UV has a variety of conveyor belts in stock and ready to be made. See below for details, visit Miltec’s website, and if you are ready for a quote, check out our online form.