The future

of UV curing.

UV curing systems for 30+ applications:

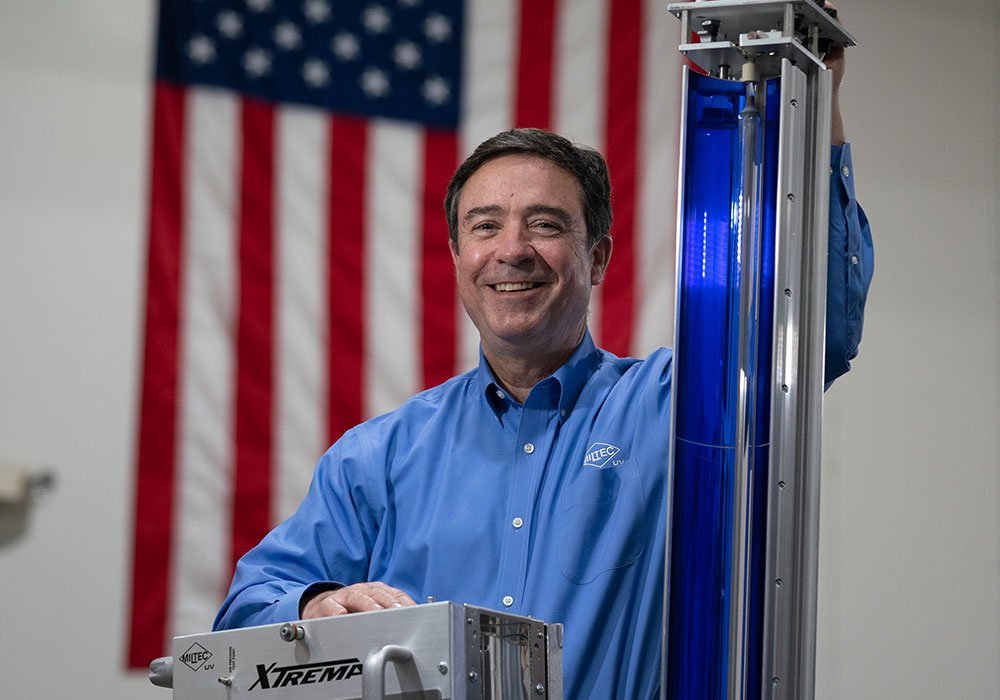

UV Curing Systems

We design and manufacture an extensive variety of UV curing equipment, giving you the flexibility to choose the most suitable UV technology for your application.

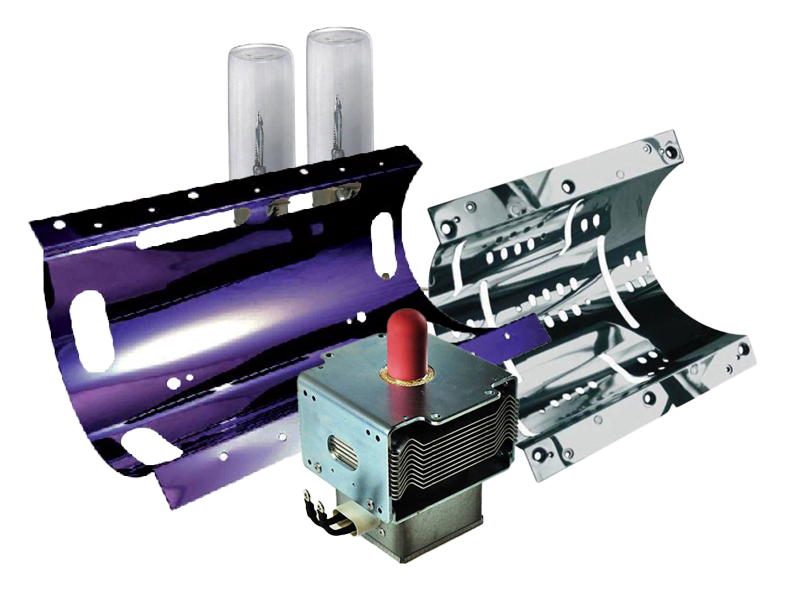

UV Parts & Accessories

We carry one of the largest selections of UV curing parts

and accessories in the country. Most orders ship the

same day.

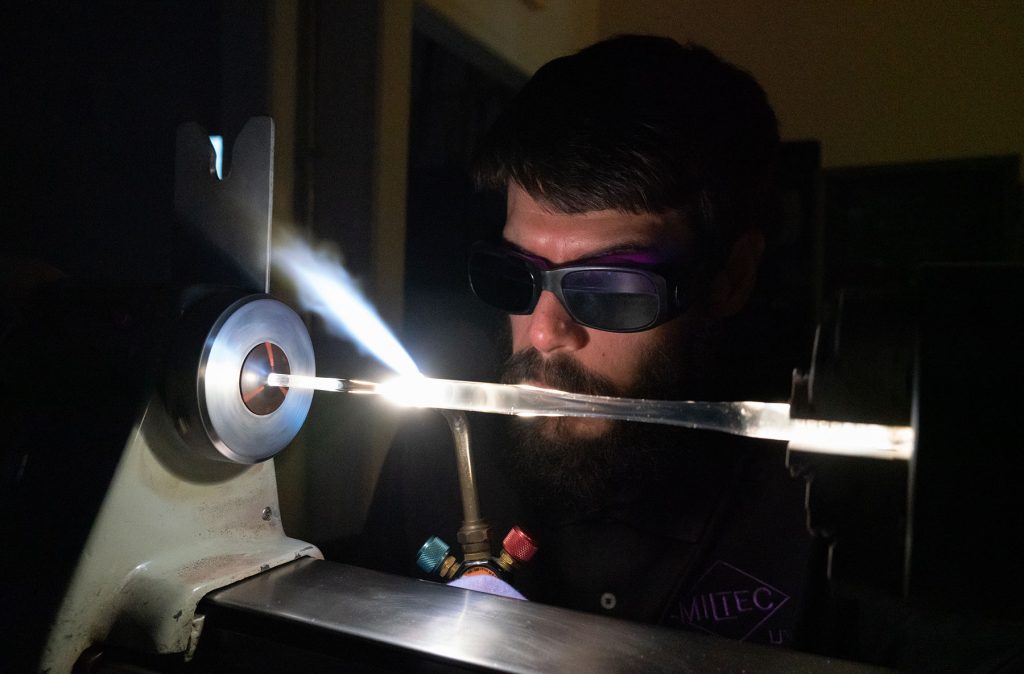

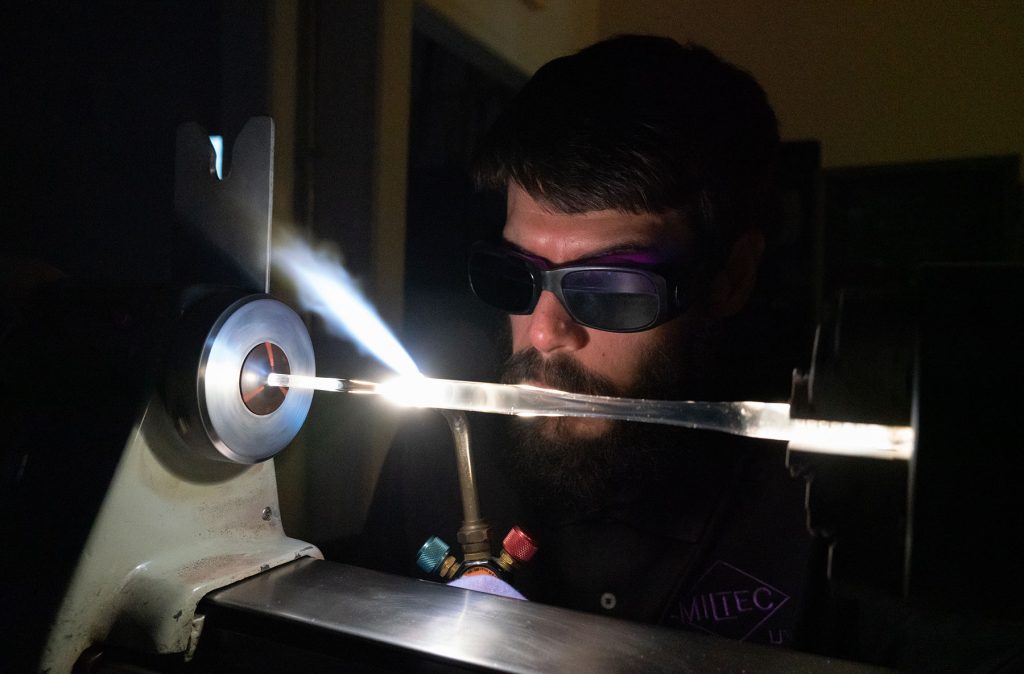

Our people set us apart.

Our friendly team of experts is always here to help.

Count on them for solutions, ideas, support, and guidance.

Knowledge Center

Sharing. Innovating. Inspiring.

-

Is Your UV Curing System Ready for Summer?

EIGHT Maintenance Tips to Keep Your UV curing system Running Smooth all summer With summer fast approaching, it’s time to give your UV curing system a spring cleaning to help reduce pesky heat issues before they arise. Just like you might do a spring cleaning at home to prepare for the warmer weather, it’s a…

-

UV Power Supply Test Points Save Time & Money

Test points for microwave UV power supplies allow maintenance teams to quickly and easily troubleshoot the system’s three basic circuits: the photocell, filament, and magnetron current. Located on the front or back of the power supply, some units may have three sets and others only two but all the systems that utilize these tools have…

What our clients say

Always here to help.

If you have questions about our products or services, just give us a call.