When curing with UV, maintaining consistent and accurate results may be a bit challenging without the use of an instrument called a UV radiometer. Each UV process, whether microwave, arc, or LED, requires a specific output from the UV source to provide an adequate cure of the chemistry being used.

The best way to verify that your UV source is providing the correct UV output for the process is by using a Radiometer to measure the Irradiance (W/cm2) and the Energy Density (J/cm2) of the UV output.

By verifying the adequate level of UV output, the possibility of running an uncured product can be significantly reduced, increasing your return on investment (ROI) by minimizing loss of material, cleanup, and labor. In today’s world of competitive manufacturing, a UV radiometer is a necessary tool.

TYPES OF UV RADIOMETERS

Depending on your specific needs, there are several different types of radiometers available.

The first is the UV PowerMap ® II, a compact, profiling UV radiometer tool for analyzing multi-lamp systems during production with a single pass, used for measuring peak intensity and total energy density in one spectral region. You can select a Power Map II that reads one of the four different wavelengths – UVA, UVB, UVC, or UVV – with a sampling rate of up to 2,048 samples per second.

This upgraded version is 60% smaller than the previous UV Power Maps and UV Power Map Plus™ and offers several new features. The UV PowerMap ® II has a “Pause Mode” which allows the user to “pause” the unit to collect information on up to eight different UV systems. The data is then transferred to a computer where it breaks down the information into individual files.

With the UV PowerMap ® II, you can view and compare two sample readings together and, using the PowerView Software III, calculates the UV output difference automatically. It’s the perfect tool for analyzing multi-lamp production systems with just a single pass, reducing troubleshooting time from hours to minutes and decreasing costly downtime. The UV PowerMAP® II improves your process control, reduces product waste, and increases your bottom-line profits.

The next type of UV radiometer includes the upgraded the UVICURE® Plus II Profiler and the UV Power Puck® II Profiler. In addition to measuring peak irradiance (W/cm2) and energy (J/cm2) on a production line, they also have the ability to measure and display the irradiance profile information directly on the radiometer, making it easier to detect poorly performing UV lamps in a multi-lamp system.

The UVICURE® Plus II Profiler is a single-channel radiometer (measuring either UVA, UVB, UVC or UVV) and the UV Power Puck® II Profiler, which measures all four-channels simultaneously.

Both Profiler radiometers present the data on the puck’s front display but also allow you to transfer the irradiance profile and data to a computer for further analysis, evaluation, and storage.

The UVI Cure and UV Power Puck are also offered in a standard version without the capacity to transfer the data to a computer. The standard version data is visible on the puck’s front display only.

If you have an industrial UV LED system, the recommended radiometer is the LEDCure ™. This radiometer is equipped with Total Measured Optic Response (TMOR™). Everything within the radiometer “optics stack” is included in the overall instrument response, not just in the optical filter. This technology provides consistency as well as repeatable and accurate readings, measuring peak irradiance (W/cm2) and energy (J/cm2) on a production line. This UV radiometer has a high dynamic range of 40 W/cm2 and a user-changeable battery. Various LED specific response bands are available.

The UV LEDCure ™ radiometer also has two versions. The standard version presents the data on the puck’s front display in a graph or reference mode. The profiler version also uses the front display, with the added ability to download the irradiance profile to a computer. With the profiler version, you can compare different LEDs, power levels, exposure times, and the height above the substrate.

TROUBLESHOOTING WITH UV RADIOMETERS

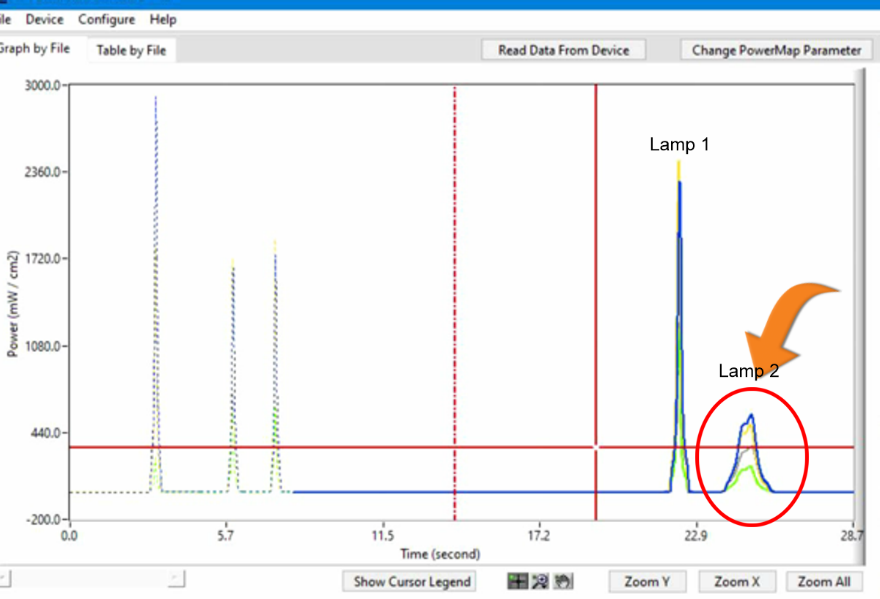

If the UV output from the UV source is deemed to be low, radiometer data can help pinpoint the problem area. Most UV Profiler radiometers today include software that can read the data on a computer. Using this method, a visual image is very easy to interpret, even for non-technical people. For example, using the image below, you can see that a two-lamp system shows lamp #2 very low, compared to Lamp #1. Assuming both lamps are set to the same power level, you can easily tell which lamp has a problem. This is especially helpful when troubleshooting multi-lamp UV systems.

USING A UV RADIOMETER TO COMPARE DATA

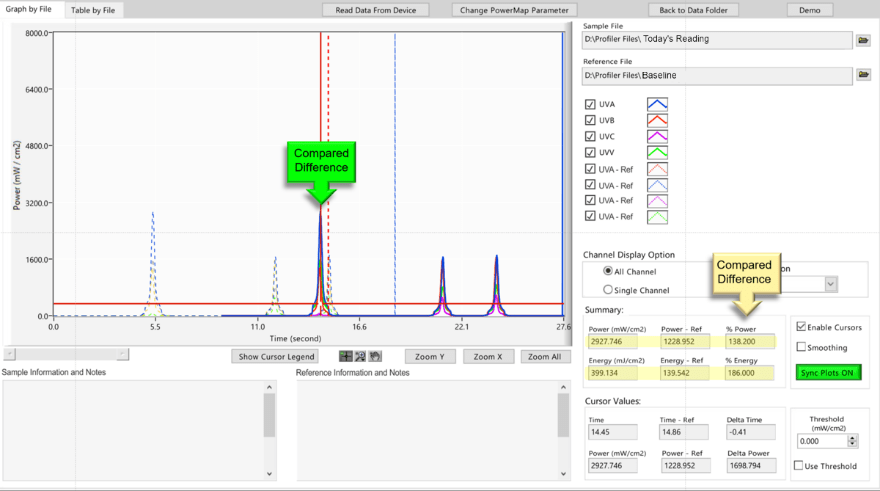

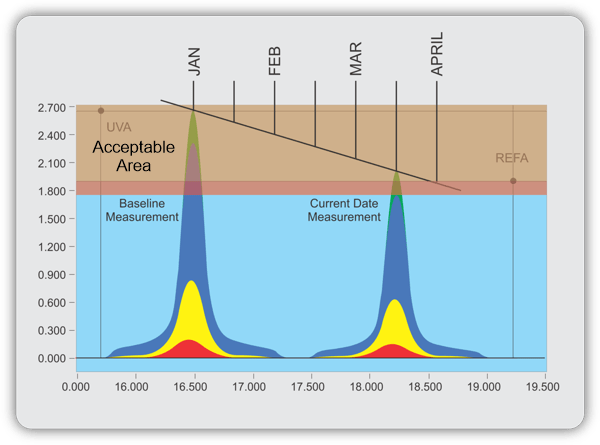

You can use a UV radiometer to compare baseline readings (new lamp, new reflector, etc). By comparing new radiometer readings with a baseline reading, you can see the percent and numerical difference of UV degradation over time.

By logging and tracking this information, it can help determine when maintenance will be required.

UV radiometers are a vital tool for the UV curing industry. Different types of radiometers are available, depending on your specific manufacturing needs. By measuring and tracking your UV output, you can reduce the possibility of running an uncured product, minimizing waste, labor, and clean-up time.

For more information, visit the UV Radiometer section of the Miltec website. Written by: Bob Malone