Selecting the right wood floor can be one of the most important decisions you make for your home, since it’s often the one piece that ties a room together. Not all wood floors are created equal and selecting the right wood floor isn’t just about picking out the color. There are other factors to consider that impact the aesthetics and performance.

SPECIES

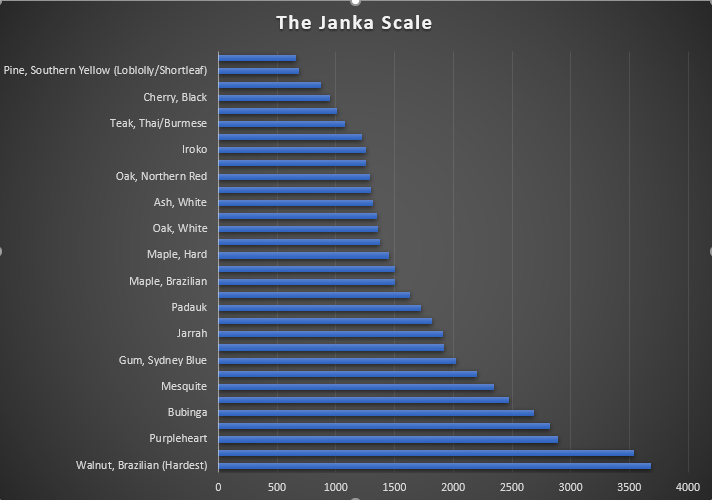

Throughout the world, there are more than 50 domestic and imported species of wood to help create the look you want. Selecting the right wood floor depends on your lifestyle, budget, and personal preference, there is a wood out there for you. When selecting the right wood floor, the species of wood needs to be highly considered. Some species of hardwoods are harder than others and — depending on your lifestyle — is something to take into consideration. The hardness of solid wood is measured using a system called The Janka Scale. This scale will determine how well a species can withstand dents and dings by the amount of pound-force required to push a .444-inch steel ball halfway into the wood; the higher the number, the harder the wood. Other factors such as how wood is cut and what type of finish is applied to the wood can also affect the durability.

Below are various species that have been measured using The Janka Scale:

TYPES

There are two types of wood floorings to choose from when making your flooring decision. The first to consider is an engineered wood floor. Engineered wood floors consist of multiple layers of wood, with a top layer made of high-quality wood. The remaining layers are bonded together to prevent the floor from shifting during contraction and expansion stages (depending on temperatures). Engineered wood is ideal for any room — including basements — because these floors expand significantly less than solid wood flooring. These types of floors can sometimes be sanded and refinished depending on the thickness of the top layer. The second option is solid wood flooring which is made of one piece of wood and can be sanded and refinished several times due to its integrity.

FINISHING METHOD

Site-finished or pre-finished wood floors are options on how you can have your floors finished. A site-finished floor simply means that the finish is applied to your floor once it has been installed in your home. This offers the best customization and there is greater control over the stain and sheen applied. The disadvantage is that it does require longer drying times, meaning you cannot walk on the floors immediately. The other option is pre-finished wood flooring, where the finish is applied at the manufacturing plant and is ready to be walked on by the time it leaves the plant. Customers know that the wood color they selected is the one they will receive from the plant. Coatings and stains on wood floors are applied and cured using UV light, providing the manufacturer consistency in their finished products. UV curing also allows manufacturers to be more efficient and increase production output providing less chance for backorders. Customers will also see a benefit in pre-finished wood floors because UV curing the coatings and stains results in a more durable floor.

SHEEN

Selecting the right wood floor also involves deciding what type of sheen you want. There are a few different options to choose from. The floor with the highest shine will be in the glossy group. Glossy finishes offer the most reflection, although you will notice scratches much easier on this type of sheen. The next step down in gloss would be a semi-gloss finish. This finish still provides some shine but not as much as a glossy finish. A satin sheen is the next one in line. This sheen provides a very low shine to the floor and reflects a small amount of light; it’s a good medium for those who want just a bit of sheen mixed with a bit of matte. The last sheen offered is a matte finish. These types of finishes offer an almost non-reflective finish and provide the best coverup for scratches. In the end, the less sheen, the less scratches and wear that will be apparent.

STYLE

Selecting a strip, plank, parquet, or end grain are all different styles of flooring to choose. Selecting the right wood floor involves one of these styles and will not restrict you on choosing the species of wood, color, or width. It comes down to your own personal preference. When selecting one of these styles, remember that strip flooring is approximately three inches wide, giving the illusion of more space. Plank flooring is three inches or wider, providing a more casual or luxurious look to your room. Generally, the wider the plank, the more expansive the floor. Parquet flooring can vary in sizes and creates a non-linear look to your room. It displays several square and rectangular patterns in distinctive geometric designs, suitable for formal spaces. Lastly, end grain allows you to see the wood grain along the top of the wood. It provides a very distinctive look and one of the most durable flooring materials on the market. It’s made by continuously cross cutting or slicing logs into blocks or rounds. The annual growth rings from the tree become exposed in all pieces. This type of floor is typically custom ordered and is a bit more complex to install.

Taking the time and selecting the right wood floor can help ensure you end up with a floor that meets the aesthetics and performance you desire. Taking these steps will lead you in the right direction:

- Select the right location in your home.

- Establish a budget.

- Review your lifestyle to determine what type of floor and style would be best.

- Find a professional that can help order and install your wood floor.

- Learn how to maintain your new floor.

Cited: National Wood Flooring Association, “Real Wood Real Life.” The Homeowner’s Handbook to Real Wood Floors, February 2019

Written by: Ana Hetzel